Control of the RESTA HTH3-20 mobile screener (sorter)

Reference

- country: Czech Republic – coarse screener/sorter for JPP trans s.r.o., a Czech company operating in the field of transportation and disposal of construction waste, demolition and earthworks

- implementation: RESTA s.r.o.

- year of implementation: 2023

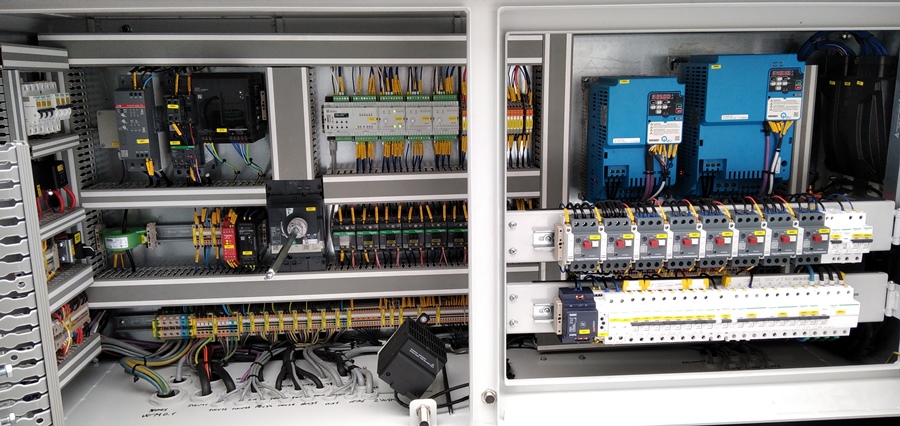

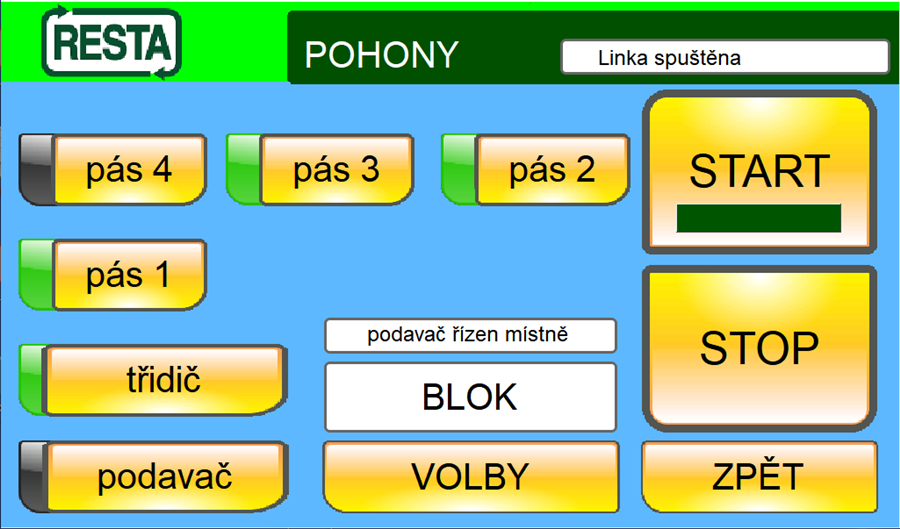

- control system: PLC Tecomat Foxtrot 2, Danfoss XL-104, OP Weintek

- software: Mosaic, EasyBuilder Pro

The company RESTA s.r.o. from Prerov is the largest Czech manufacturer of mobile crushing and sorting equipment and one of the largest operators of this technology in the Czech Republic. For JPP trans custom manufactured and supplied a HTH31200x3000 coarse screener/sorter, which is controlled by our PLC Tecomat Foxtrot. It is a mobile screener on a hydraulic crawler chassis. It can process construction waste, soil, bitumen, coal, gravel and natural aggregate into three output fractions. The output of the machine is 60 – 200 tons per hour depending on the type of sorting surfaces and the type of material. Power supply from the 3x400V AC mains or using a built-in 65 kVA diesel-electric generator. Travel and some functions are controlled by radio remote control. The weight of the machine is 17 tons.

In general, these machines are used in quarries, surface mines, land and reclamation activities, sand pits, landfill recycling, reinforced concrete disposal, etc.

Tecomat Foxtrot controls:

- voltage, states of contactors and frequency converters of electric drives

- controls the starting and stopping of belt conveyors (4 belts in total), sorters and feeders in a sequence based on the movement of the processed material through the machine

- "BLOCK" mode – programmed function of blocking individual drives; when one of the belts stops, the system also automatically switches off the drives that are in the blocking row. This will stop the flow of the material and prevent the blocked part from clogging. When a malfunction is detected, the indicator light on the control panel lights up, the operator is alerted by a horn, and a malfunction message is displayed on the operator panel screen

- "UNBLOCK" mode – individual drives can be controlled manually without mutual blocking

Communication of PLC Tecomat Foxtrot with other systems

- communicates with OP Weintek via the MODBUS TCP/IP protocol

- communicates with Danfoss XL-104, which controls the hydraulic parts of the machine, via digital inputs and outputs

See how the coarse sorter works in this video.