Integration of heating and cooling systems in production halls Flídr, s.r.o.

Reference

The company FLÍDR, s. r. o. and Flídr plast, s. r. o., with a thirty-year history, has been loyal to metalworking and machining since the beginning, it also produces precise plastic moldings, especially for the automotive industry, and also supplies instrumentation to the healthcare industry, e.g. operating lights, medical gas sources and distributions, etc. The whole group Flídr employs around 300 workers and has almost 6,000 m² of production area available.

With the gradual development of production and the differentiation of the portfolio, there was a need to integrate previously decentralized technological equipment of measurement and regulation and IRC (individual regulation of cooling) into one control system.

Pro tyto účely a s tím spojené vizualizace procesů vytápění a chlazení byly zvoleny PLC automaty Tecomat Foxtrot spolu se SCADA/HMI systémem Reliance.

Tecomat Foxtrot byl implementován ve čtyřech rozvaděčích rozmístěných v prostorách výrobního závodu. Pro efektivní výměnu dat jsou jednotlivá PLC propojena skrze síť PLCNet. Každý rozvaděč je vybaven také HMI panelem (ID-36), který slouží k lokálnímu ovládání příslušných technologických částí.

For these purposes and the associated visualization of heating and cooling processes, Tecomat Foxtrot PLC central modules were chosen together with the Reliance SCADA/HMI system.

Tecomat Foxtrot was implemented in four switchboards located in the areas of the production plant. For efficient data exchange, the individual PLCs are connected via the PLCNet network. Each switchboard is also equipped with an HMI panel (ID-36), which is used for local control of the relevant technological parts.

The Tecomat Foxtrot system controls the following:

-

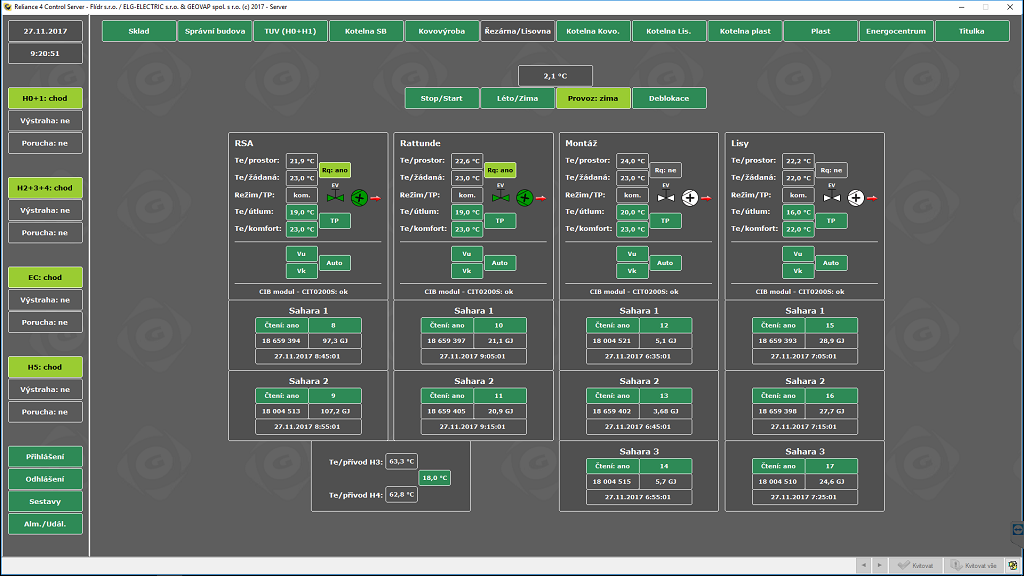

operation of IRC equipment in approximately 20 premises - warehouses and production areas

-

water heating

-

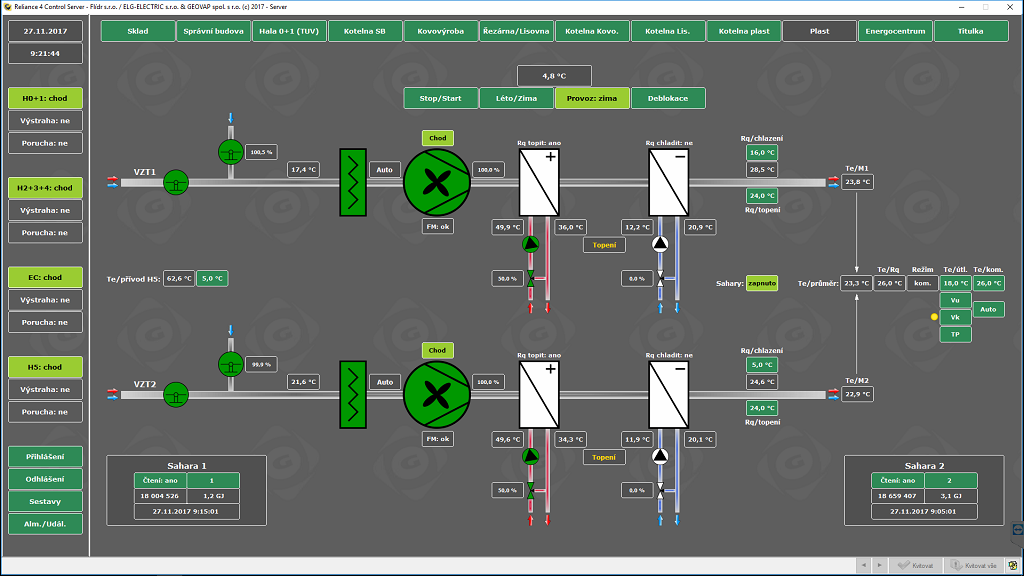

heating and cooling of the production hall – 2 air-conditioning units)

-

4 boiler rooms - mixing nodes

-

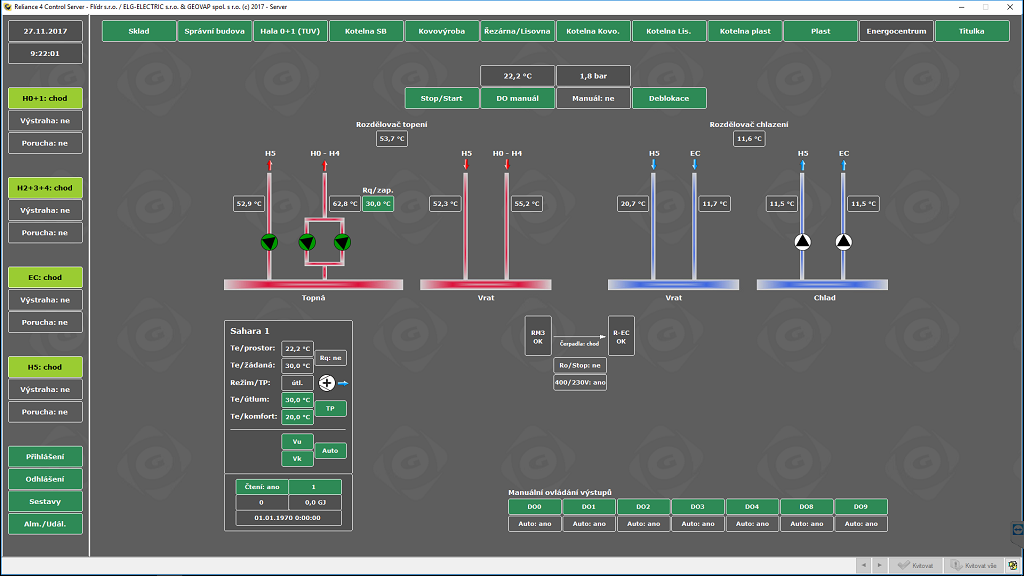

distribution of heat and cold from the energy center

-

heat consumption in individual operations – M-Bus communication

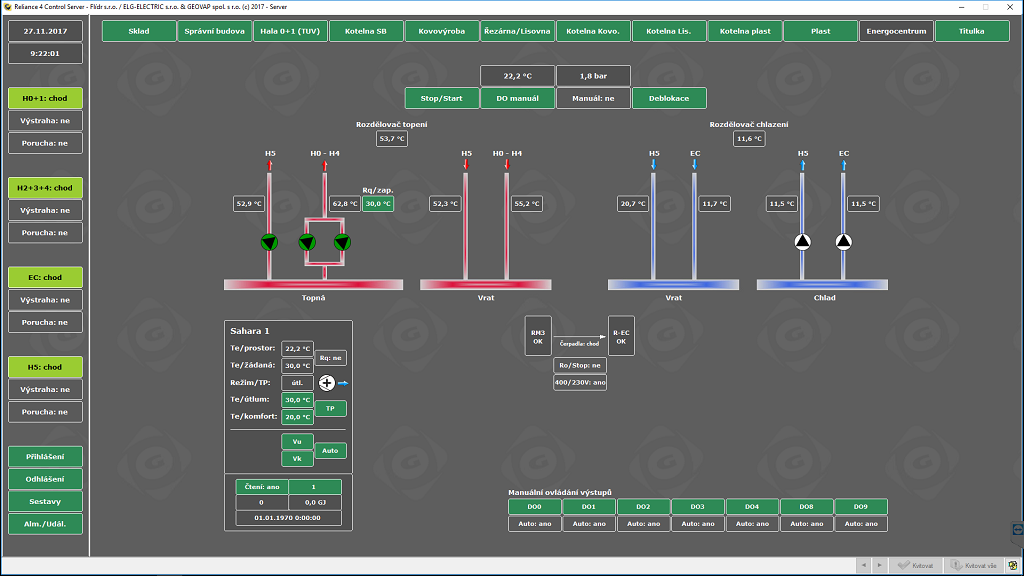

Visualization: Main screen

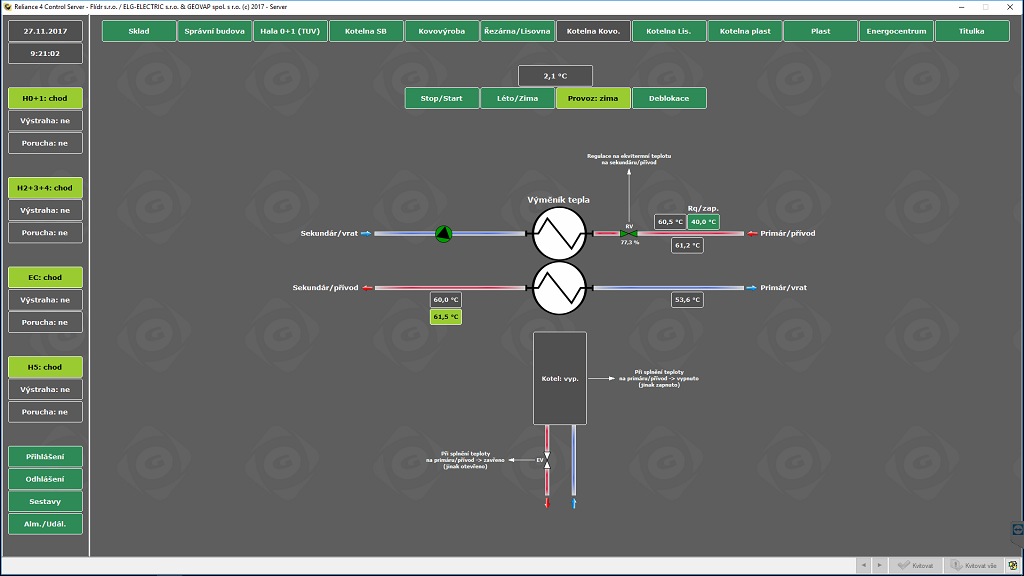

Visualization of heat and cold distribution from the energy center

All data from the control system is transferred to the dispatch computer where the Reliance SCADA system is installed. This allows the operator to monitor the status of individual technological units via visualization screens, set parameters, monitor alarm messages or view data history in tabular reports. The operator also benefits from remote access to visualization and data using a tablet.