Terminal OEE (Overall Equipment Effectivenes)

Reference

- Country: Czech Republic

- Name Terminal OEE

- Implemented by: LAMAL s.r.o.

- Date: 2011-2012

- Control system: Foxtrot CP-1004

- Software: Mosaic, implementation into current company visualization with Reliance 4, Connectivity into SQL, SAP and acces system CEVIS

During May 2011 company Lamal s.r.o. has realized a project, where a customer did need to develop a universal device with following requirements:

- integration into any production technology

- technology availability monitoring

- technology production rate monitoring

- device overall efficiency monitoring OEE **

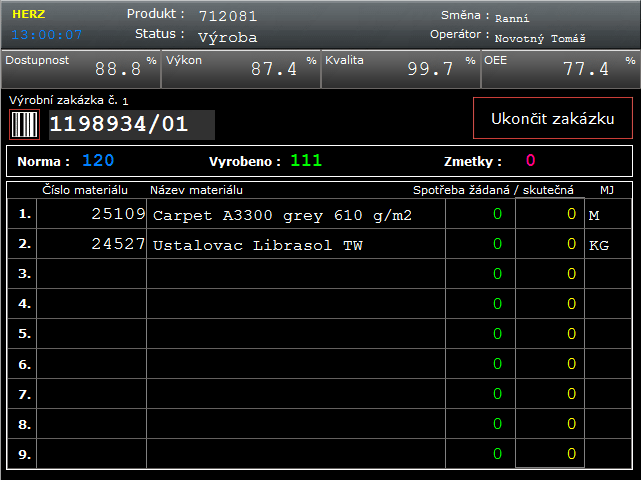

- possibility of depreciation of the materials

To fulfill above mentioned requirements they had to figure out following terms:

- product a device with small dimension and simple assembly with suitable HMI interface for operator and support of industrial communication busses like Profibus, Modbus etc.

- implement a RFID card reader into the device and ensure the conectivity into database of access system CEVIS

- install the bar code reader and ensure the connectivity into SQL database server and company software SAP

As suitable hardware for this application there was choosen PLC Tecomat Foxtrot CP-1004 with 5,7" touch panel ID-28 and WMR card reader.

As suitable software there was full suitable existing SCADA Reliance software with SQL support. In combination with Mosaic software they reached full functionality.

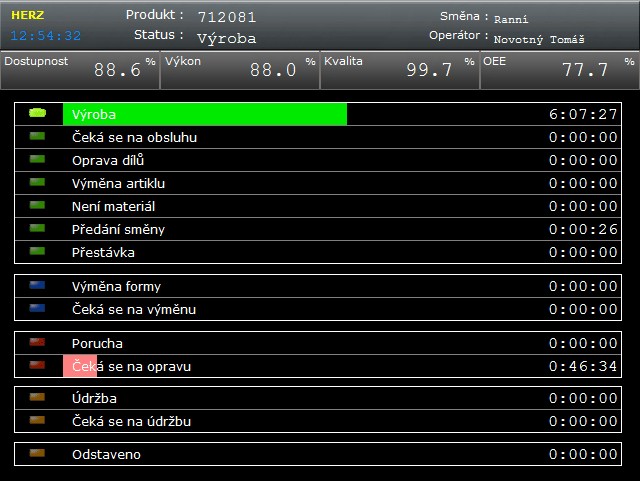

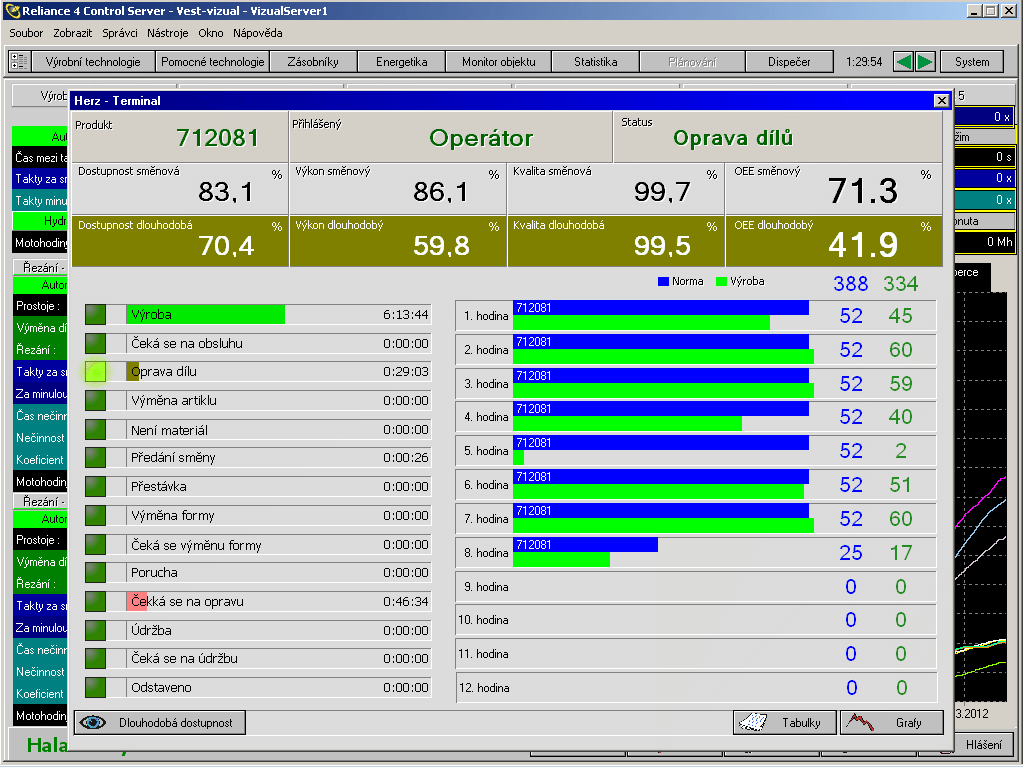

The benefits for investor are especially monitoring of:

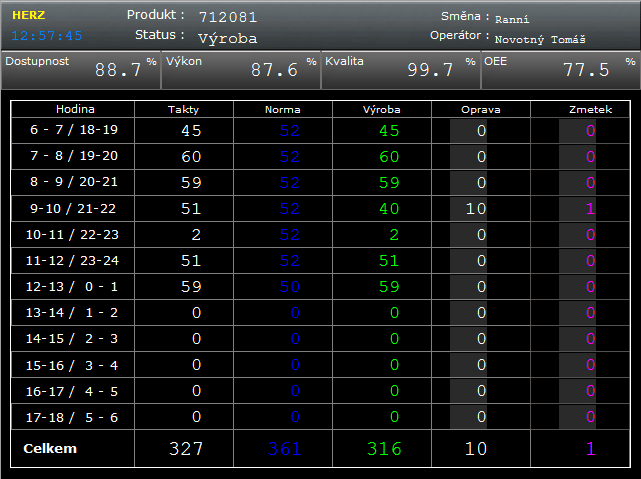

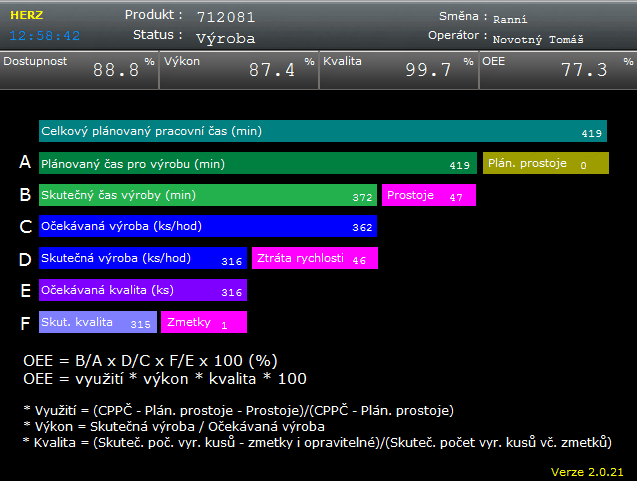

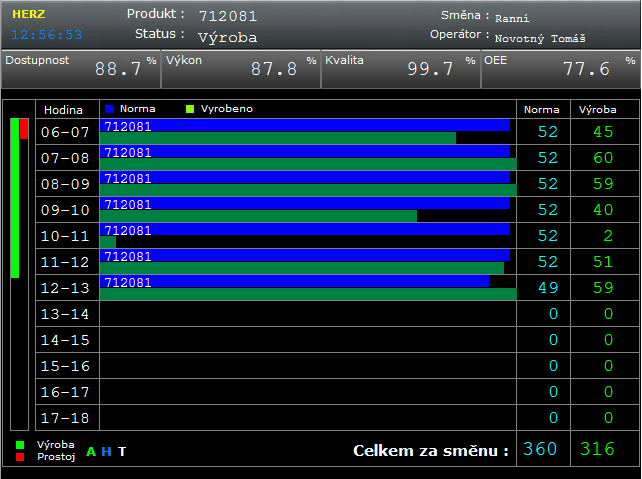

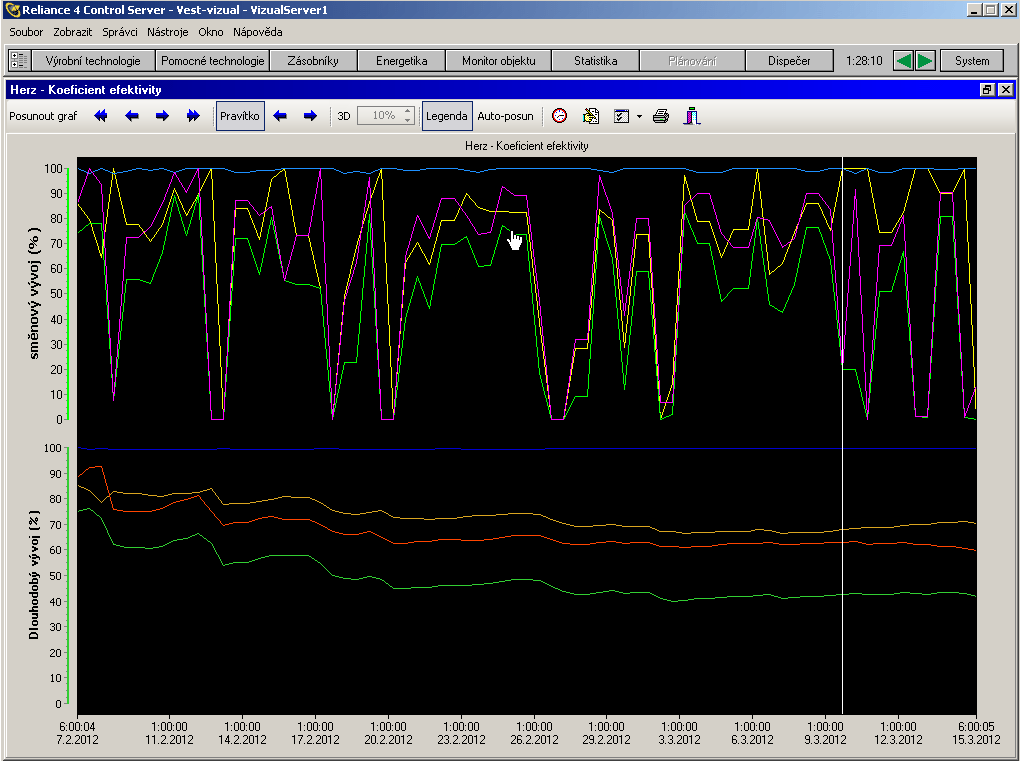

- a trend of OEE coefficient development with graphical visualization

- current and long-term technology availability, for instance the lenght of shutdown because of errors, maintenance, lack of material, waiting for operator, waiting for reparation etc.

- current performance compared with standardized performance and with possibility of graphical vizualization at large-screen monitor

- reject rate with sources of rejects

- operative depreciation of material

- operaror arrival and departure

- who and when did repairs, exchanges of molds in technology etc.

With use of GSM module they also completed the service of sending SMS message when technology availability changes.

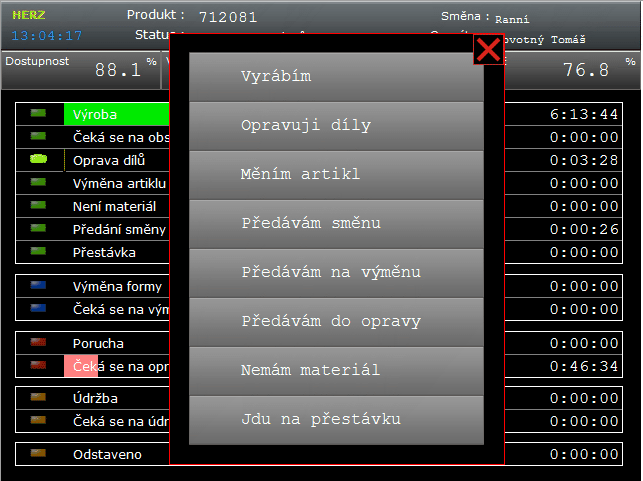

Example:

- Operator due to defects of technology changes the availability to "transferring to repair", to be sent SMS message "Production interrupted, transferring to repair."

- Called maintenance operator changes availability to "I am performing the repair", SMS message to be sent "Repair begins".

- Maintenance operator has finished repair and change availability to "Transferring to production", SMS message to be sent "Rapair has finished, transferred to production"

- Operator changes availability to "Production in process", SMS message to be sent "Production has begun".

A chief of production or any other responsible person is able at any time find out when the technology stopped production, how long did it take the maintenance operator came in and when the technology restored production.

** OEE - Overall Equipment Effectiveness

Overall Equipment Effectiveness is especially in car industry expressed by OEE coefficient. This coefficient is determined by 3 indexes: availability, performance and quality. It is expressed in %.